Flexray Slots

As automobile development has continued apace, some new highly complex and critical subsystems have emerged. Simple networks such as CAN Bus and LIN Bus have long handled communications among controllers and electromechanical automotive systems, but an enhanced communication bus eventually became necessary to handle higher-bandwidth connections.

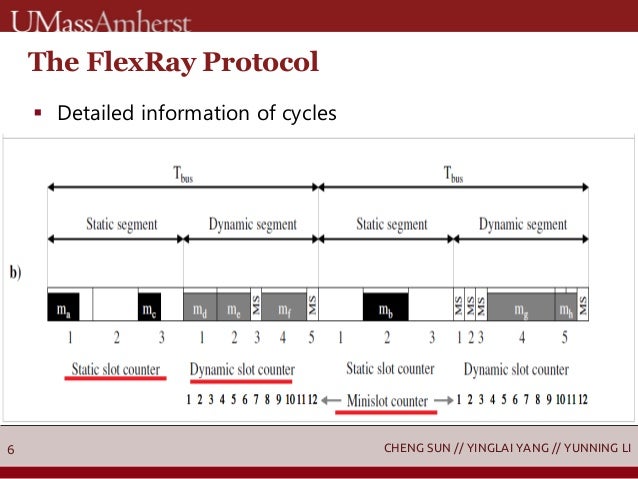

. Each slot is statically allocated to a node or unused. If a node uses in one FlexRay cycle, other nodes cannot use the same index in following cycles. Reserved slots for deterministic data that arrives at a fixed period. Dynamic Segment The dynamic segment behaves in a fashion similar to CAN and is used for a wider variety of event-based data that does not require determinism. Disadvantages of Flexray. The FlexRay nodes assigned to the static slots can transmit the static messages assigned to the static slots during periodic communicative operation. The precondition for this process are synchronized local counters, each of which are incremented at the beginning of a static slot. The FlexRay Interface does not directly access the FlexRay hardware (FlexRay Communication Controller and FlexRay Transceiver), but by means of one or more hardware-specific Driver modules. In order to access the FlexRay Communication Controller(s), the FlexRay Interface.

Accordingly, a consortium developed standards for what came to be called FlexRay. As currently implemented, it comprises the bus for what is known as drive-by-wire, steer-by-wire and break-by-wire. These new mechanisms enhance safety, performance and economy to no small degree. But in the event any of these fail, the consequences could be catastrophic. For this reason, the electrical bus that provides their connectivity must be highly reliable. That mandate is central to FlexRay on both hardware and software levels.

FlexRay is deterministic and fault-tolerant to a degree that makes it suitable for a chassis that at times may be hurtling along a steep, winding road or traversing rough terrain, perhaps operated by a less-than-expert driver. The bus and all its components must last the life of the vehicle without even momentary failure.

FlexRay should not be construed as a replacement for CAN Bus any more than LIN Bus takes its place at the other end. A look at the specifications shows why: In regard to speed, LIN Bus is 40 kbit/sec, CAN Bus is 1 Mbit/sec, and FlexRay is a ten-fold increase, 10 Mbit/sec. LIN Bus cabling consists of one wire, CAN Bus cabling consists of two wires, and FlexRay needs two or four wires. A much higher price for FlexRay is just the cost of doing business in the context of the high-performance power train, drive-by-wire, active suspension and adaptive cruise control.

FlexRay operates on either one or two channels. Cabling is unshielded twisted pair(s), which convey differential signaling to reduce noise from outside. (In addition to the one or two twisted pairs, power and ground lines are connected to the nodes.) The optional dual-channel hookup makes possible enhanced fault tolerance as well as increased bandwidth, which equates to higher-speed performance.

For a bus with multiple drops, only the end nodes need termination resistors to match the 80- to 110-Ω characteristic impedance of the media. Proper termination is especially important in FlexRay because it routinely operates at much higher frequencies than its predecessors. When a system is being prototyped, termination resistance frequently must be adjusted to obtain satisfactory performance. Currently, FlexRay interfaces on supplied circuit boards often incorporate resistive terminations, eliminating problems in impedance matching.

FlexRay, as well as CAN Bus and LIN Bus networks, often make use of elementary multi-drop topologies. FlexRay may incorporate more advanced star topologies, which can be integrated to good effect within the overall project. Typically this topology suits designs where reliability, performance and costs are appropriate for high-tech applications.

Multiple engine control units (ECUs) can connect along a single FlexRay bus in multi-drop topology. The multi-drop format has been widely used in CAN Bus and LIN Bus. Because designers are familiar with this topology, they are sometimes inclined to stay with what works. But in reality the star network is preferable. In the star, individual links connect directly to a central hub, as in a LAN Ethernet network. One advantage is that the star topology can span greater distances because the line needn’t meander from node to node. And even where it doesn’t approach the maximum length, shorter is always better for economy and performance as well as exposure to physical damage.

Another advantage in the star topology is that if there’s a shorted device or physical damage to a cable, the outage is confined to the affected node as opposed to a string of nodes.

Inline and star topologies are sometimes combined to form a hybrid configuration. This is a good way to go because simplicity and low cost of the inline topology can be combined with the performance and reliability of the star.

In FlexRay, time is of the essence. The problem that must be confronted in any multi-drop bus is that there will be contention for bus resources and consequent data corruption if two or more nodes on a bus attempt to transmit simultaneously. To prevent contention, various techniques have been found to work. Arbitration, for example, is employed on CAN Bus. This ensures potential competing nodes will yield to that node whose message has the highest priority. The disadvantage is that the arbitration overhead wouldn’t support the high data rates typical of FlexRay.

FlexRay, accordingly, uses a different method to avoid contention on the bus. This new type of data bus uses a communication pattern that is uniform for both static and dynamic data. There is a time division multiple access (TDMA) scheme that manages data flow among the nodes, each of which waits its turn for access to the bus.

The communication cycle is unique within separate embedded systems, which is to say it is customized for the application. In a typical 1-msec time interval, there is a static segment, a dynamic segment, a symbol window, and a much shorter network idle time.

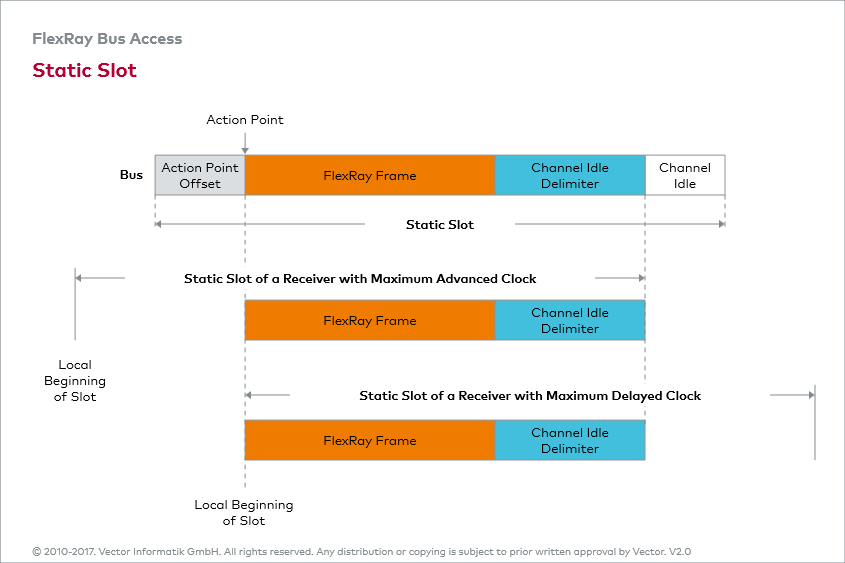

In the static segment, deterministic data is placed in preset slots. The dynamic segment contains non-deterministic event-based data. The symbol window is dedicated to shop-keeping and initiating the network when data is needed. Network idle time is devoted to synchronizing the separate clocks at each node. This is important for avoiding data collisions. A macrotick, usually 1 μsec, is the unit of time employed at every node for the synchronization process.

Flexray Slot

An important FlexRay implementation on autos is the brake-by-wire system. Small hydraulic cylinders actuate the calipers at all four wheels in the traditional manner, but this action is now electrically controlled. It is feasible to have not necessarily equal braking at each wheel. The amount of braking at each wheel depends on road conditions and input from sensors within the chassis. The result is a safer traveling experience characterized by enhanced performance and economy.

The demands of braking a fast-moving vehicle bring some inherent risks. To meet the challenge, FlexRay was designed to be fault-tolerant to a high degree. The same comments apply to the steering system. Additionally, the steering system retains its traditional mechanical linkage between the operator and the front wheels, so in the event of electrical bus failure, the vehicle can hold the road.

Flexray Slot Id

For those who design embedded networks, it is highly beneficial to have a database that describes all nodes. This is particularly true when working with FlexRay because there is such a proliferation of parameters that must be set and managed. One such database is the Field Bus Exchange (FIBEX). It is an XLM-based standardized file that describes multiple automotive serial networks including CAN Bus and FlexRay. FIBEX has been successful in describing the innovative automotive network including configuration parameters, frames, signals, schedules and relevant coding at the bit level.

The FlexRay protocol is a unique time-triggered protocol that provides options for deterministic data that arrives in a predictable time frame.FlexRay is a serial communication technology that is used in particular for data communication in very safety-critical use areas in the automobile.

Differential signaling on each pair of wires reduces the effects of external noise on the network without expensive shielding. FlexRay nodes typically also have power and ground wires available to power transceivers and microprocessors. FlexRay manages multiple nodes with a Time Division Multiple Access scheme. Every FlexRay node is synchronized to the same clock, and each nodes waits for its turn to write on the bus. Because the timing is consistent in a TDMA scheme, FlexRay is able to guarantee determinism or the consistency of data deliver to nodes on the network. This provides many advantages for systems that depend on up-to-date data between nodes.

- Static Segment

Reserved slots for deterministic data that arrives at a fixed period. - Dynamic Segment

The dynamic segment behaves in a fashion similar to CAN and is used for a wider variety of event-based data that does not require determinism.

Disadvantages of Flexray:

The bus has certain disadvantages like lower operating voltage levels and asymmetry of the edges, which leads to problems in extending the network length.

Ethernet may replace FlexRay for bandwidth intensive, non-safety critical applications.